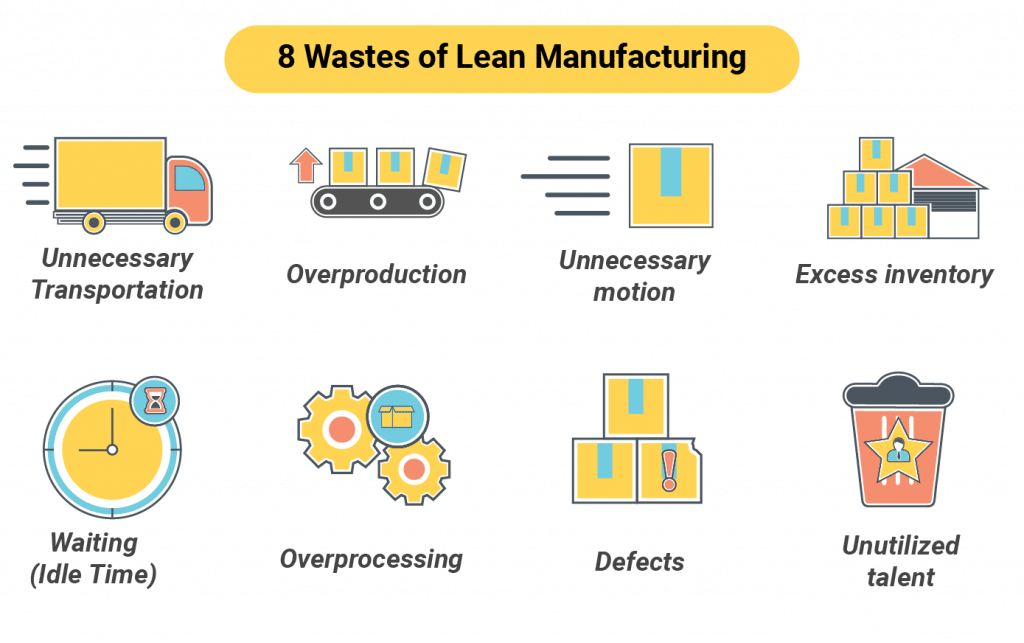

What Is Waste In Lean Management . By understanding what each of the wastes. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean. downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. this article will explore the most common sources of waste in any organization, explore the benefits of. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen.

from www.fogwing.io

By understanding what each of the wastes. downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean. this article will explore the most common sources of waste in any organization, explore the benefits of.

Guide On Lean Manufacturing Fogwing

What Is Waste In Lean Management define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. By understanding what each of the wastes. downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. this article will explore the most common sources of waste in any organization, explore the benefits of. the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean.

From kissflow.com

8 Wastes of Lean How to Identify and Eliminate Them What Is Waste In Lean Management this article will explore the most common sources of waste in any organization, explore the benefits of. By understanding what each of the wastes. the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. downtime refers to the 8 wastes of lean manufacturing services that get in the way. What Is Waste In Lean Management.

From www.unisanuk.com

3 tips on how to Lean your business waste management. Unisan UK What Is Waste In Lean Management define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. this article will explore the most common sources of waste in any organization, explore the benefits of. By understanding what each of the wastes. downtime refers to the 8 wastes of lean manufacturing services. What Is Waste In Lean Management.

From dxogclvku.blob.core.windows.net

What Are The Different Types Of Waste In Lean at Wilbur Thompson blog What Is Waste In Lean Management define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. By understanding what each of the wastes. this article will explore the most common sources of waste in any organization, explore the benefits of. downtime refers to the 8 wastes of lean manufacturing services. What Is Waste In Lean Management.

From blog.unex.com

What is Lean Waste? [The 7 Wastes of Lean Manufacturing] What Is Waste In Lean Management downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. By understanding what each of the wastes. this article will explore the most common sources of waste in any organization, explore the benefits of. define waste and value, discover the 8 wastes of lean, and learn how to eliminate. What Is Waste In Lean Management.

From www.dreamstime.com

The Eight Wastes on Lean Methodology Process Diagram. Flat Diagram with What Is Waste In Lean Management the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean. this article will explore the most common sources of waste in any organization, explore the benefits of. By understanding what each of the. What Is Waste In Lean Management.

From www.fogwing.io

Guide On Lean Manufacturing Fogwing What Is Waste In Lean Management the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean. this article will explore the most common sources of waste in any organization, explore the benefits of. By understanding what each of the. What Is Waste In Lean Management.

From www.eflexsystems.com

Identifying the 8 Lean Manufacturing Waste in Your Organization What Is Waste In Lean Management define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. By understanding what each of the wastes. the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. downtime refers to the 8 wastes of lean manufacturing. What Is Waste In Lean Management.

From digitalelearnings.com

Wastes of Lean Manufacturing Digital ELearning Statistics, Six Sigma What Is Waste In Lean Management By understanding what each of the wastes. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. The “8 wastes” methodology, originating from the toyota production system. What Is Waste In Lean Management.

From www.huimfg.com

8 Wastes of Lean Manufacturing Downtime Infographic What Is Waste In Lean Management By understanding what each of the wastes. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. this article will explore the most common sources of waste in any organization, explore the benefits of. The “8 wastes” methodology, originating from the toyota production system (tps),. What Is Waste In Lean Management.

From www.sprintzeal.com

Lean Waste Management A Definitive Guide 2023 What Is Waste In Lean Management By understanding what each of the wastes. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean. this article will explore the most common sources of waste in any organization, explore the benefits of. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8. What Is Waste In Lean Management.

From www.cannsult.org

What Are The 8 Wastes of Lean? What Is Waste In Lean Management define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. By understanding what each of the wastes. downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. the seven wastes of lean manufacturing are what we. What Is Waste In Lean Management.

From www.quality-assurance-solutions.com

The 7 Wastes of Lean What Is Waste In Lean Management By understanding what each of the wastes. downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. this article will explore the most common sources of waste in any organization, explore the benefits of. the seven wastes of lean manufacturing are what we are aiming to remove from our. What Is Waste In Lean Management.

From www.alamy.com

Eight wastes accordingly to lean methodology Stock Photo Alamy What Is Waste In Lean Management downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean. define waste and value,. What Is Waste In Lean Management.

From www.sprintzeal.com

Lean Waste Management A Definitive Guide 2023 What Is Waste In Lean Management By understanding what each of the wastes. The “8 wastes” methodology, originating from the toyota production system (tps), and is a key foundational lean. this article will explore the most common sources of waste in any organization, explore the benefits of. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8. What Is Waste In Lean Management.

From mungfali.com

Lean 8 Wastes Chart What Is Waste In Lean Management the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. this article will explore the most common sources of waste in any organization, explore the benefits of. downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. define waste and. What Is Waste In Lean Management.

From www.creativesafetysupply.com

The 8 Wastes of Lean Poster (White) What Is Waste In Lean Management the seven wastes of lean manufacturing are what we are aiming to remove from our processes by removing. this article will explore the most common sources of waste in any organization, explore the benefits of. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via. What Is Waste In Lean Management.

From www.smartsheet.com

The Complete Guide to Lean Project Management Smartsheet What Is Waste In Lean Management downtime refers to the 8 wastes of lean manufacturing services that get in the way of process flows. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. By understanding what each of the wastes. The “8 wastes” methodology, originating from the toyota production system. What Is Waste In Lean Management.

From blog.igus.eu

What is Lean Management and how do you work lean? igus Blog What Is Waste In Lean Management this article will explore the most common sources of waste in any organization, explore the benefits of. By understanding what each of the wastes. define waste and value, discover the 8 wastes of lean, and learn how to eliminate the 8 wastes from your organization via kaizen. the seven wastes of lean manufacturing are what we are. What Is Waste In Lean Management.